Reliability verification and testing of absolute encoders in the aerospace field

Jan 15,2025

By:Epoch

Reliability verification and testing of absolute encoders in the aerospace field Reliability verification and testing of absolute encoders in the aerospace field Here's a closer look at the topic:

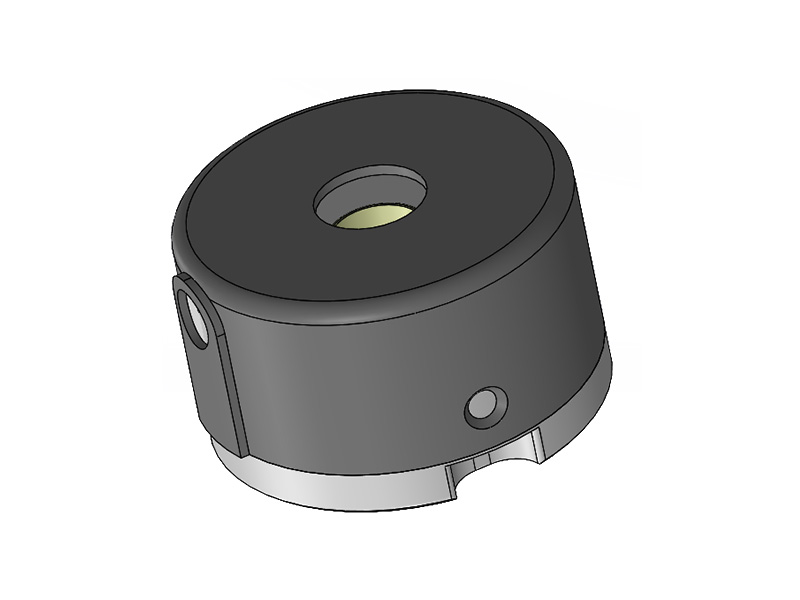

In the aerospace field, the absolute encoder is a key component of position feedback, and its reliability is directly related to the safety, stability and performance of the aircraft. Therefore, strict reliability verification and testing of absolute encoders is an important means to ensure the quality of aircraft and improve flight safety.

Purpose of reliability verification and testing

The main purpose of reliability verification and testing is to evaluate the performance stability and durability of the absolute encoder under specific environmental conditions to ensure that it can meet the high requirements of the aerospace field in practical applications.

Reliability verification and testing methods

Environmental stress test:

The absolute encoder is subjected to environmental stress tests by simulating extreme environmental conditions in the aerospace field, such as high temperature, low temperature, high humidity, strong magnetic field, strong vibration, etc.

Monitor encoder performance changes under these conditions, including signal output stability, resolution retention, etc.

Accelerated burn-in test:

Using an accelerated aging model, such as the Arrhenius formula, the absolute encoder is subjected to environmental stresses higher than the actual operating conditions to accelerate its aging process.

The mean time to failure (MTBF) and reliability level of the encoder are evaluated by counting the failures during the test.

Vibration and shock test:

The vibration and shock environment of the aircraft during takeoff, flight and landing are simulated, and the vibration and shock test of the absolute encoder is carried out.

Check the structural integrity, signal output stability and positioning accuracy of the encoder under the action of vibration and shock.

Electromagnetic compatibility test:

Evaluate the performance of the absolute encoder in an electromagnetic interference environment to ensure that it can work properly and output signals accurately.

The test includes electromagnetic radiation emission, electromagnetic radiation sensitivity, electromagnetic conduction emission and electromagnetic conduction sensitivity.

Standards and requirements for reliability verification and testing

The aerospace field has strict standards and requirements for the reliability verification and testing of absolute encoders, and these standards are usually formulated by national or industry authorities, such as MIL-HDBK-781, GJB899A-2009 and so on. These standards should be strictly observed during the testing process to ensure the accuracy and reliability of the test results.

The significance of reliability verification and testing

Improve product quality: Through reliability verification and testing, the problems existing in the design and manufacturing process of the absolute encoder can be found in time, and corresponding improvement measures can be taken to improve product quality.

Ensure flight safety: The reliability of the absolute encoder is directly related to the safety performance of the aircraft. Through rigorous testing, it can be ensured that the encoder can work stably and accurately in practical applications, so as to ensure flight safety.

Reduce maintenance costs: Reliable absolute encoders reduce failure rates, reduce maintenance costs, and improve the operational efficiency of the aircraft.

The reliability verification and testing of absolute encoders in aerospace field is a complex and important process. Through rigorous environmental stress testing, accelerated aging testing, vibration and shock testing, and electromagnetic compatibility testing, the performance stability and durability of the encoder can be evaluated to ensure that it can meet the high requirements in practical applications. At the same time, these tests also help improve product quality, ensure flight safety and reduce maintenance costs. Therefore, in the aerospace field, the reliability verification and testing of absolute encoders is indispensable.