Incremental encoders are widely used in the field of precision measurement

Jan 15,2025

By:Epoch

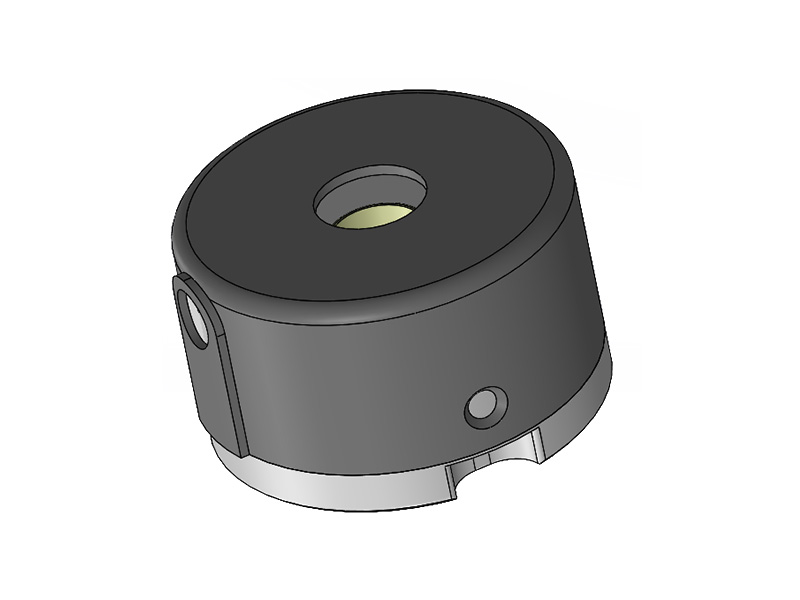

Incremental encoders have become indispensable tools in the realm of precision measurement, offering unmatched accuracy and reliability in a wide range of applications. Their ability to provide continuous positional feedback makes them ideal for systems that require high-precision control and monitoring.

Key Advantages for Precision Measurement

High Resolution and Accuracy: Incremental encoders are capable of achieving very high resolutions, often measured in thousands or even millions of pulses per revolution. This high resolution translates into extremely accurate positional feedback, enabling precision measurement down to sub-micron levels.

Non-Contact Operation: Unlike some other position sensors, incremental encoders operate non-contactingly. This means there is no physical wear between the sensing elements and the moving parts, leading to longer service life and reduced maintenance requirements.

Robust and Reliable: Incremental encoders are designed to withstand harsh industrial environments. They are resistant to dust, dirt, and moisture, and can operate reliably over a wide range of temperatures. This robustness ensures that they can be used in a variety of precision measurement applications, including machine tools, automation systems, and robotics.

Scalability: Incremental encoders are available in a wide range of sizes and configurations, making them suitable for applications with different spatial and performance requirements. From tiny encoders for use in compact systems to large encoders for heavy-duty machinery, there is a solution to fit every need.

Applications in Precision Measurement

Machine Tools: Incremental encoders are commonly used in machine tools such as lathes, milling machines, and grinding machines. They provide precise positional feedback to the control system, enabling high-accuracy machining and fabrication.

Automation Systems: In automation systems, incremental encoders are used to monitor the position and movement of robotic arms, conveyors, and other automated equipment. This ensures that the systems operate within tight tolerances, improving productivity and reducing waste.

Robotics: Robotics applications often require high-precision positioning and movement control. Incremental encoders provide the necessary positional feedback to enable these capabilities, enabling robots to perform complex tasks with great accuracy.

Aerospace and Defense: In the aerospace and defense industries, precision is paramount. Incremental encoders are used in a variety of applications, including gimbal control systems, missile guidance systems, and flight control surfaces, to ensure accurate positioning and movement.

Trends and Innovations

As precision measurement demands continue to grow, so do the innovations in incremental encoder technology. Advances in signal processing and materials science are enabling higher resolutions, better environmental resilience, and longer service lives. Additionally, the integration of incremental encoders with other sensors and systems, such as cameras and vision systems, is leading to even more sophisticated and capable precision measurement solutions.

In conclusion, incremental encoders are a cornerstone of precision measurement technology. Their high resolution, non-contact operation, robustness, and scalability make them ideal for a wide range of applications, from machine tools and automation systems to robotics and aerospace. As technology continues to evolve, we can expect to see even more innovative and capable incremental encoders in the future.