High-Precision Position Feedback

Accurate Measurements

High-Frequency Response Capability

Strong Speed Monitoring Capability

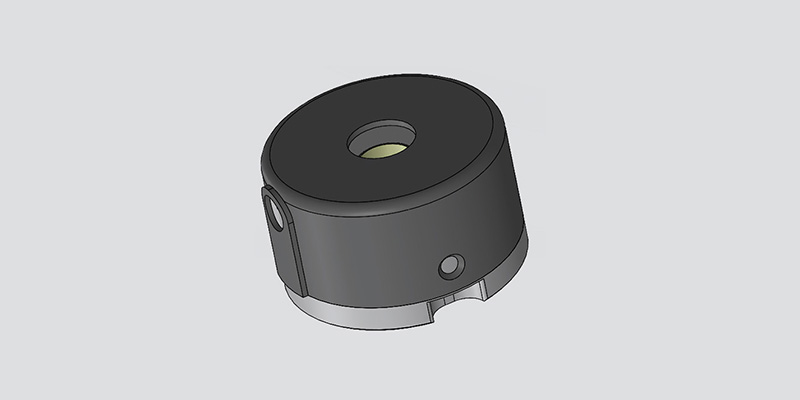

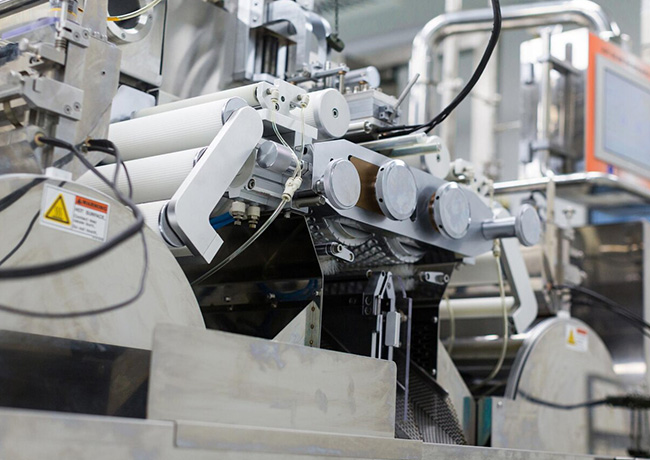

Versatility for a wide range of industrial applications.Rugged construction to ensure reliable performance under challenging conditions

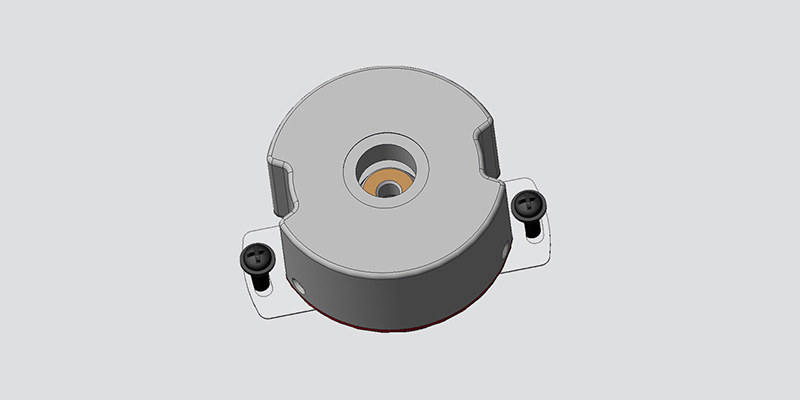

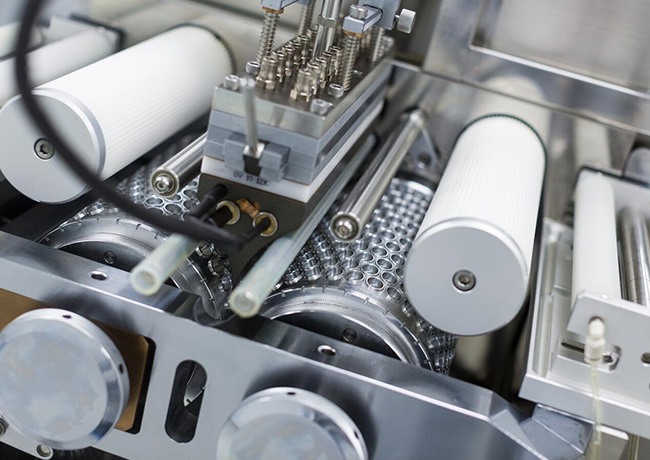

Incremental encoders feature a resolution of 1000-5000 CPR with differential output, high-frequency response up to 500 kHz, and provide precise speed and position feedback.

Details

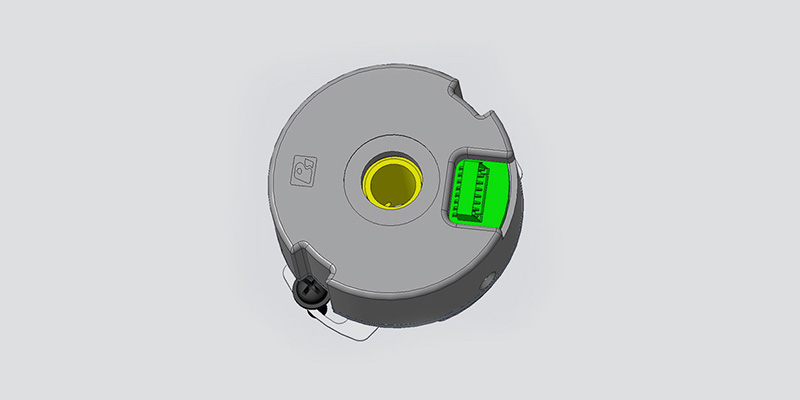

Absolute encoders provide high-resolution position feedback with 17-23 bit resolution, multi-turn counting capability of 16 bits, and absolute positioning accuracy within ±50 angular seconds using an RS485 interface.

Details

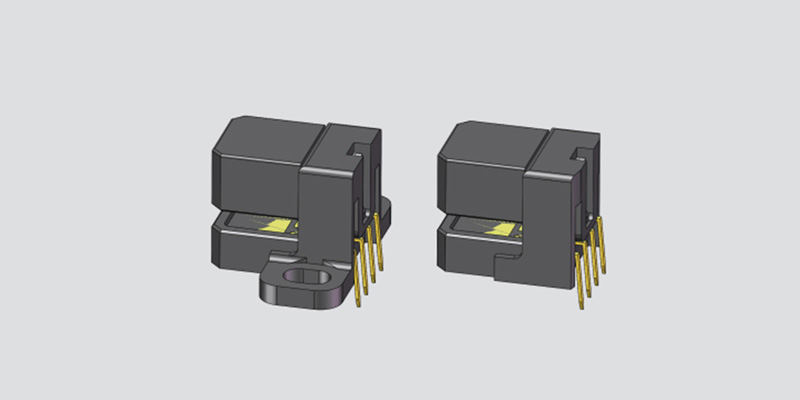

High-performance 2-channel incremental encoder, Response frequency up to 200 KHz, Integrated precision matrix receiver,Multiple mounting options, Ideal for servo motor applications.

Details

Contact Us Today to Discuss Your Project!

DetailsReady for a Custom Solution? Request Your Quote!

Tailored power solutions by power, voltage, format and application.

Explore Rotary Encoder

We are committed to delivering high-quality, innovative electronic components that empower industries to achieve greater efficiency.

Follow Us