How Servo Motor Encoders Work: Everything You Need to Know

Apr 10,2025

By:Epoch

In the field of servo motors, one crucial electronic component is the encoder. Today, we will explore what a servo motor encoder is and examine its role in a servo motor system.

What is a servo motor encoder ?

A servo motor encoder is a critical component in a servo motor system, providing precise feedback on the motor's position, speed, and direction. This feedback allows the servo controller to adjust motor performance in real-time for accurate and efficient operation.

What is the role of the encoder in the servo motor ?

The encoder in a servo motor plays a crucial role by providing real-time feedback on the motor's position, speed, and direction, enabling precise control and efficient operation. Here's a breakdown of its functions:

1.Position Feedback:

The encoder detects the angular position of the motor shaft and sends this information to the controller. This allows the servo system to accurately determine and maintain the desired position.

2.Speed Monitoring:

By observing changes in position over time, the encoder calculates the rotational speed of the motor shaft. This feedback helps regulate motor speed for smooth and consistent operation.

3.Direction Detection:

Encoders can identify whether the motor shaft is rotating clockwise or counterclockwise, ensuring proper directional control

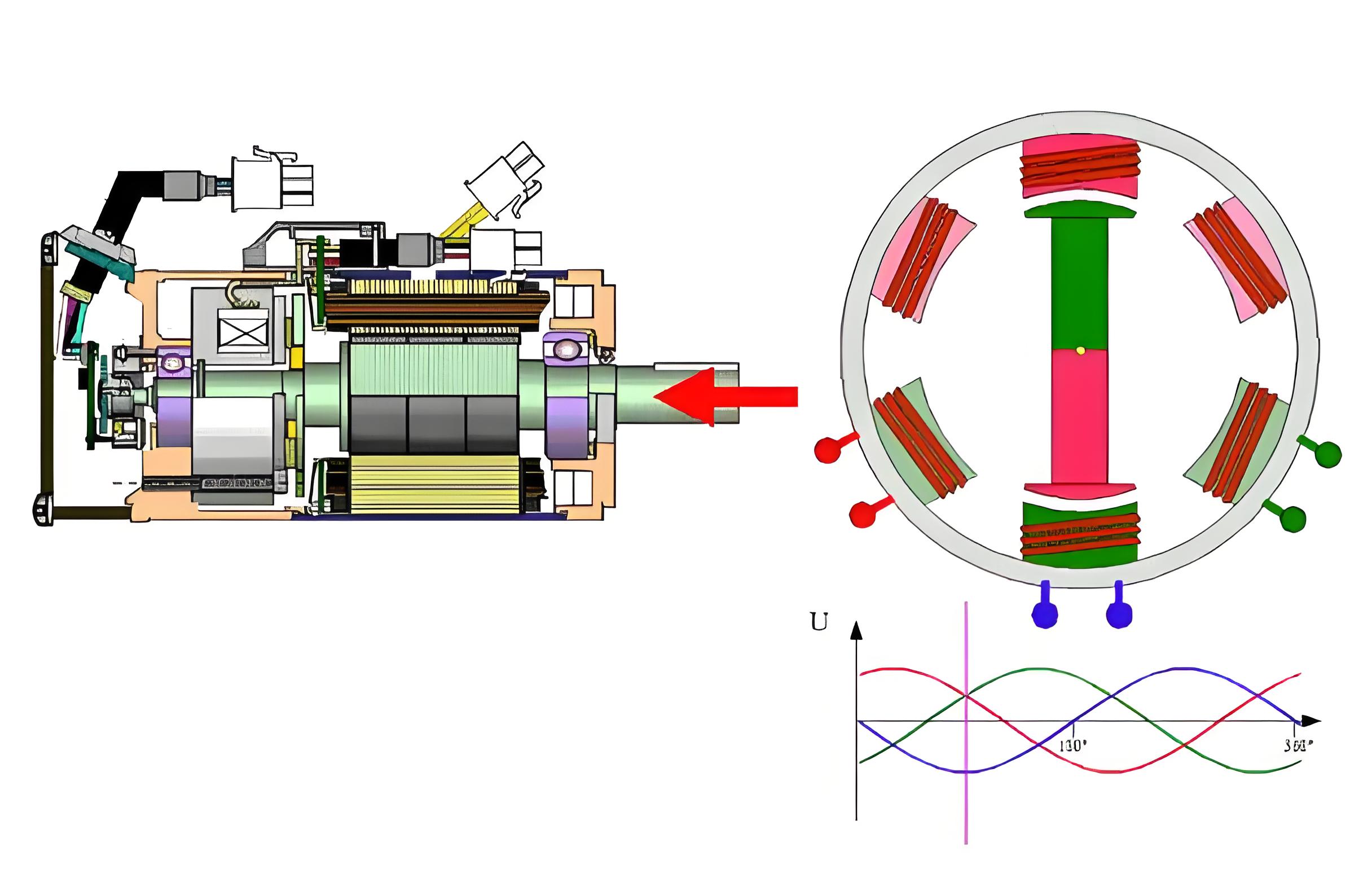

4.Commutation:

For brushless servo motors, encoders assist in commutation by aligning the rotor and stator's magnetic fields. This ensures optimal torque and efficiency during operation

5.Error Correction:

Encoders provide feedback that allows the controller to adjust for disturbances or inaccuracies, such as load changes or external forces, maintaining precise motion control

6.Types of Encoders Used

Incremental Encoders: Provide relative position feedback through pulses, requiring a reference point for absolute positioning.

Absolute Encoders: Offer unique position values for every shaft location, eliminating the need for a reference point and retaining position data even after power loss.

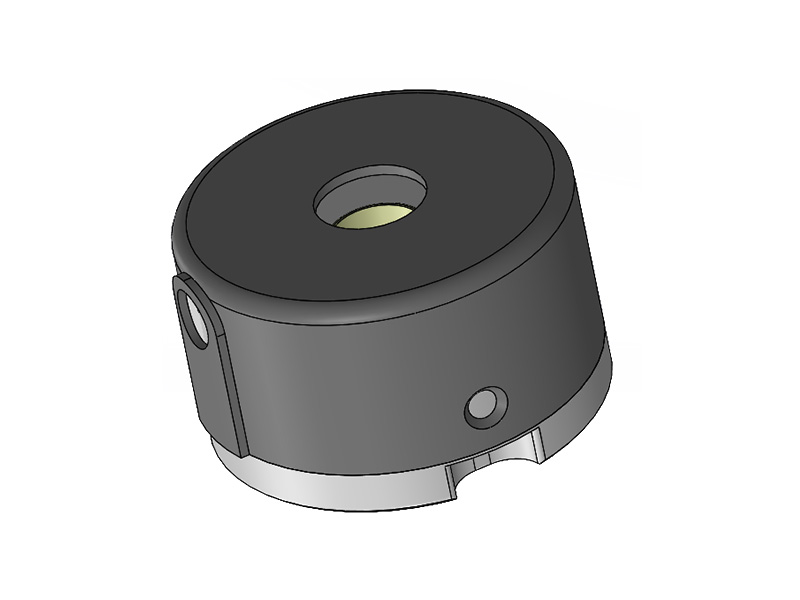

Servo Motor Encoders: Precision Feedback Solutions for Advanced Motion Control

Servo motor encoders are essential components in modern motion control systems, providing accurate feedback on position, speed, and direction. The company offers a range of high-performance servo motor encoders designed to meet the diverse needs of industrial and automation applications. Below is a detailed overview of the our company-EPOCH ELECTRONIC servo motor encoder models:

Model | Type | Key Features | Main Selling Points |

RZ35 Series | Bearing Absolute Encoder | - Resolution: 17-bit to 23-bit

- Multi-turn counter: 16-bit

- Absolute positioning accuracy: ±50 angular seconds

- RS485 interface

- Operating temperature: -20°C to +105°C

- Compact Ø35mm design | - High precision for position and speed feedback

- Wide temperature range for industrial environments

- Compact and robust design suitable for servo systems |

RZL4409A | Bearing Absolute Encoder | - Resolution: 17-bit to 23-bit

- Multi-turn counter: 16-bit

- Absolute positioning accuracy: ±50 angular seconds

- RS485 interface

- Operating speed up to 6000 rpm

- IP40 protection rating | - High reliability and precision in harsh environments

- Suitable for high-speed applications with robust mechanical design |

UZ Series (UZ4809, UZ4409) | Bearing Incremental Encoder | - Resolution: 1000–5000 CPR

- Frequency response up to 500 kHz

- Differential output

- Operating temperature: -20°C to +105°C

- Single 5V power supply | - High-speed and high-frequency response for dynamic applications

- Reliable performance in challenging conditions with robust protection |

These servo motor encoder models cater to a variety of servo motor applications, offering high precision, durability, and compatibility with industrial standards.