Absolute Optical Encoder vs Incremental Optical Encoder: Understanding the Differences

Apr 14,2025

By:Epoch

Optical encoders are essential components in motion control systems, offering precise feedback on position, speed, and direction. Among them, absolute optical encoders and incremental optical encoders are the two primary types, each catering to specific applications. This article explores their key differences, working principles, and applications.

What is an Absolute Optical Encoder?

An absolute optical encoder provides a unique digital code for each position of the encoder shaft. Even after power loss, it retains its position data, making it ideal for applications requiring precise and continuous position tracking.

Working Principle

The encoder uses an optical disc with concentric tracks containing unique binary patterns.

A light source (e.g., LED) passes through the disc's slits and is detected by photosensors.

Each shaft position corresponds to a distinct binary code, ensuring absolute accuracy.

Key Features

High Resolution: Offers resolutions up to 23 bits for precise positioning.

Power Loss Recovery: Retains position data without needing re-calibration.

Multi-Turn Capability: Tracks multiple revolutions for complex motion control.

Applications: Used in robotics, medical equipment, industrial automation, and safety-critical systems.

What is an Incremental Optical Encoder?

An incremental optical encoder measures relative motion by generating pulses as the encoder shaft rotates. It does not retain position data after power loss, requiring a reference point for re-initialization.

Working Principle

The optical disc has evenly spaced slots.

As the disc rotates, light passes through the slots and is detected by sensors.

The encoder generates pulse signals (square waves) proportional to the rotation, which are used to calculate speed and direction.

Key Features

Pulse-Based Feedback: Provides relative position and speed information.

High Frequency Response: Supports high-speed operations with resolutions up to 5000 CPR (counts per revolution).

Cost-Effective: Simpler design makes it more affordable than absolute encoders.

Applications: Commonly used in conveyor systems, CNC machines, and general industrial automation.

Comparison: Absolute Optical Encoder vs Incremental Optical Encoder

Feature | Absolute Optical Encoder | Incremental Optical Encoder |

Position Feedback | Provides unique absolute position at all times | Measures relative changes; requires reference point after power loss |

Power Loss Handling | Retains position data | Loses position data; needs re-calibration |

Resolution | High resolution (e.g., 17–23 bits) | Moderate resolution (e.g., 1000–5000 CPR) |

Output Signal | Digital code representing exact position | Pulses indicating relative motion |

Complexity & Cost | More complex and expensive | Simpler and cost-effective |

Applications | Robotics, medical devices, safety-critical systems | Assembly lines, speed monitoring, CNC machines |

Choosing Between Absolute and Incremental Encoders

The choice between an absolute optical encoder and an incremental optical encoder depends on your application's requirements:

Use an absolute optical encoder if:

Continuous position tracking is critical.

The system must recover without recalibration after power loss.

High precision is required for multi-turn or single-turn applications.

Use an incremental optical encoder if:

Relative motion or speed monitoring suffices.

Cost efficiency is a priority.

The application involves repetitive tasks like conveyor belts or milling machines.

Both absolute and incremental optical encoders play vital roles in motion control systems. While absolute encoders excel in precision and reliability under all conditions, incremental encoders offer simplicity and affordability for less demanding applications. Understanding their differences ensures you select the right encoder for your specific needs.

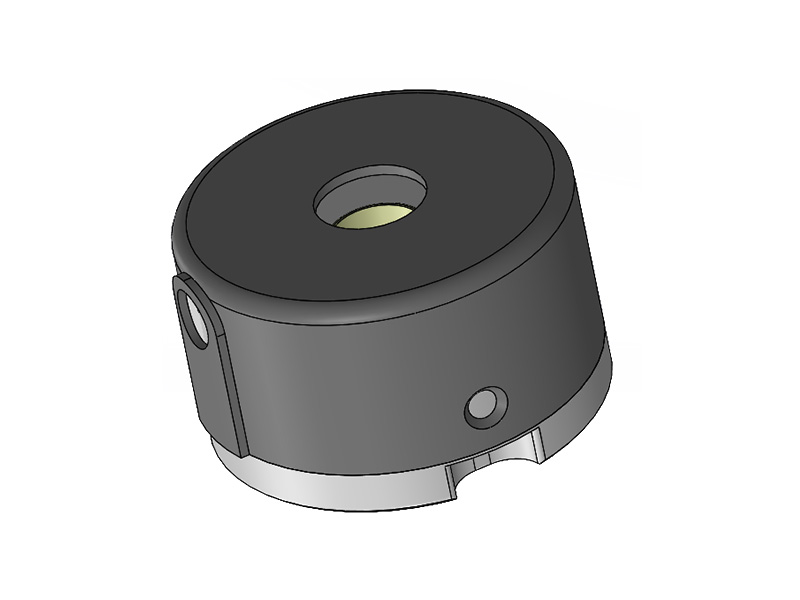

Our company specializes in supplying high-performance encoders for servo motors, including absolute optical encoders and incremental optical encoders. These devices are engineered to deliver precise feedback for position and speed control in servo drive systems, ensuring exceptional reliability and optimized performance across diverse industrial applications such as robotics, CNC machines, and automation systems.