High precision servo motor technology: Performance optimization and application innovation

Jan 16,2025

By:Epoch

In today's highly automated industrial environment, servo motors are key power transmission and control components, and their performance optimization and application innovation are directly related to the efficiency, accuracy and reliability of the entire production line. This paper aims to explore in depth the latest advances in high precision servo motor technology, especially breakthroughs in performance optimization and application innovation.

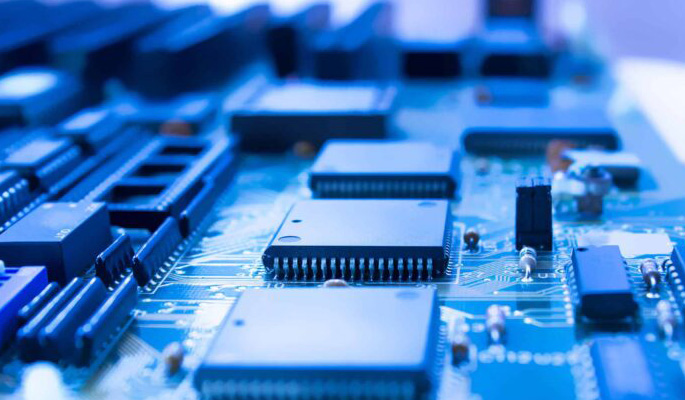

1. High precision servo motor technology overview

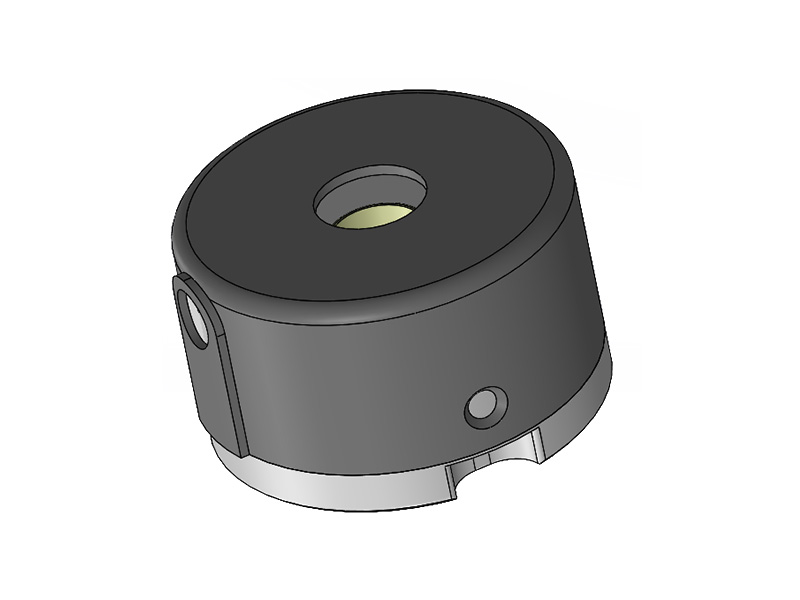

Servo motor is an executive element in closed-loop control system, its working principle is based on electromagnetic induction and servo control theory. With precise position, speed and force control, servo motors enable efficient and accurate motion control. With the continuous development of material science, electronic technology and control algorithms, high precision servo motors have made remarkable progress in resolution, repeated positioning accuracy, dynamic response and so on.

2. Performance optimization

Drive and controller technology: Advanced servo drives and control algorithms significantly improve the motor's response speed and stability, making the servo motor perform well in high-speed and high-precision control.

Material and technical innovation: The use of high-performance permanent magnet materials, optimize the motor structure and heat dissipation design, effectively improve the power density and efficiency of the servo motor, reduce energy consumption and heating.

Intelligent monitoring and diagnosis: Integrated sensor and intelligent diagnosis technology, real-time monitoring of motor operating status, early warning of potential failures, extend motor service life.

3. Application innovation

Automated production lines: High-precision servo motors play a key role in automated assembly, material handling, precision machining and other fields, improving production efficiency and product quality.

Robot technology: As the core component of robot joint drive, high-precision servo motors enable robots to perform complex and fine operation tasks, and promote the development of intelligent manufacturing.

Aerospace: In the aerospace sector, high-precision servo motors are used for critical tasks such as attitude control and rudder drive, ensuring the stability and safety of the aircraft.

Medical equipment: In medical equipment, high-precision servo motors are used in surgical robots, imaging equipment, etc., improving the accuracy and safety of medical services.

4. Future Outlook

With the rapid development of technologies such as the Internet of Things, big data and artificial intelligence, high-precision servo motor technology will develop in a more intelligent, networked and adaptive direction. In the future, servo motors will not only have higher accuracy and performance, but also have stronger self-learning and self-optimization capabilities to adapt to more complex and changeable industrial application scenarios.

High precision servo motor technology is the cornerstone of modern industrial automation, and its performance optimization and application innovation are of great significance to promote industrial upgrading and improve production efficiency. Through the comprehensive analysis of high precision servo motor technology, this paper presents the latest achievements in performance optimization and application innovation, and looks forward to its future development trend. We believe that with the continuous progress of technology, high-precision servo motors will play an important role in more fields, bringing more convenient, efficient and intelligent solutions to human production and life.